Support for modeling an monitoring of engineering design processes

Engineering design processes are highly complex and dynamic inasmuch unforeseen changes occur frequently at process runtime. In this paper we present the process management system PROCEED that aids process managers and process participants in planning and enacting the work processes in plant design projects. It is based on the commercial lifecycle engineering tool Comos. PROCEED exceeds the state of the art in process management in several ways. The models used to represent running design processes incorporate aspects of project plans and workflow instances to reflect the current planning and execution states of work processes. Workflow definitions are used to define best practices for repetitive process parts and are enacted to guide process participants. PROCEED ensures consistent changes of process models even at process runtime. A process manager can resort to numerous progress measures in order to get exact quantitative information about the performance of a process.

DYPROTO – tools for dynamic business processes

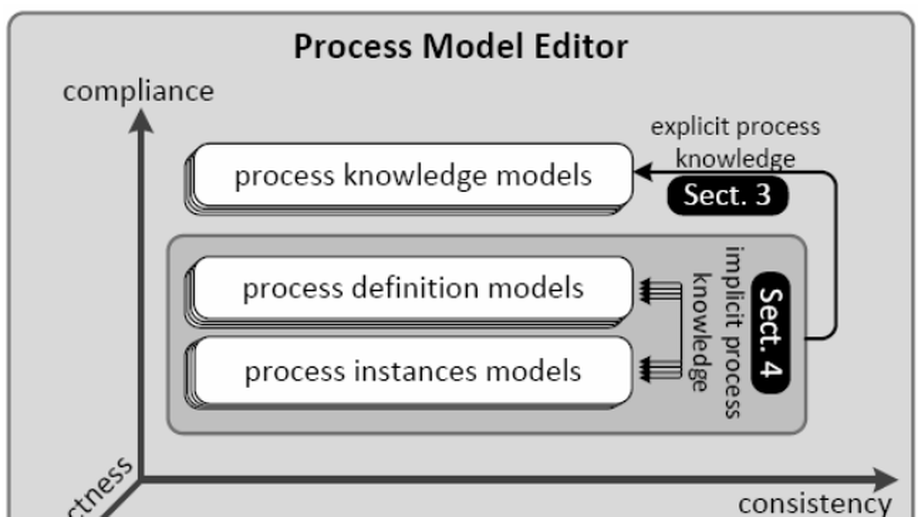

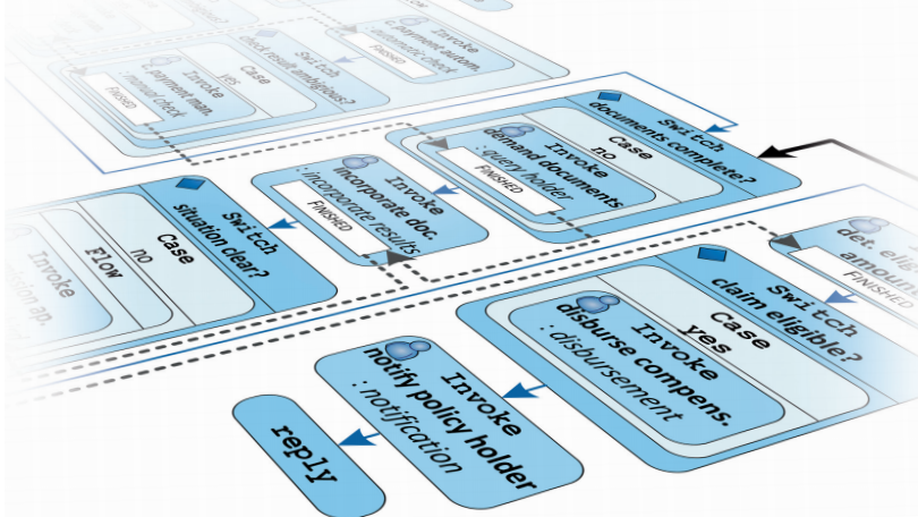

In this article, we present research results about tools for supporting dynamic business processes. This research work has been conducted in a three-year cooperation between our department and an IT service provider for insurance companies. Our partner’s process management system (PMS) is rather aligned with static processes, whose structure is not changed at process run time. Therefore, we contribute an approach for obtaining dynamic process execution support based on this static PMS by automatically augmenting existent WS-BPEL process definitions and run time data. Dynamically changeable processes are presented to process participants as graphical models by a process model editor. This editor aids process participants with performing dynamic changes inasmuch as it is aware of explicit and implicit technical and professional process knowledge and detects violations against this knowledge in dynamically changed process instance models. We delineate how explicit process knowledge can be graphically modelled and exploited in automatic checks using OCL-constrained and integrated meta-models. Checks versus explicit knowledge are complemented by checks versus implicit knowledge which is contained in other process definition and process instance models. These checks include process similarity computations based on graph grammar formalisms and tools.

Management dynamischer Geschäftsprozesse auf Basis statischer Prozess-Managementsysteme (Dissertation)

In dieser Arbeit wird ein Prozessmanagementsystem beschrieben, das auch dynamische Prozesse unterstützt. Dynamische Änderungen können von Prozessbeteiligten über strukturelle Änderungen an Modellen bereits laufender Prozesse durchgeführt werden.

Tool Support for Dynamic Development Processes

Development processes in engineering disciplines are highly dynamic. Since development projects cannot be planned completely in advance, the process to be executed changes at run time. We present a process management system which seamlessly integrates planning and enactment. The system manages processes at the project management level, but goes beyond the functionality of project management systems inasmuch as it both monitors and controls development processes and supports enactment of tasks through a work environment. However, the process management system does not provide process automation as performed in workflow management systems. Therefore, we have developed tools for integrating process management and workflow management such that repetitive fragments of the overall development process may be enacted in workflow management systems and monitored in the process management system. Even in the case of repetitive process fragments, the need for deviations from the workflow definition may occur while a workflow is being enacted. Thus, we have also realized a tool which allows to perform dynamic changes of workflows during enactment. Altogether, dynamic development processes are supported through a synergistic combination of process and workflow management systems, integrating process planning and enactment.

Flexible Multi-Dimensional Visualization of Process Enactment Data

The management of development processes is a challenging task and needs adequate tool support. In the course of a development project, many different engineering and management processes are enacted and have to be controlled. The management data has an inherently multidimensional character. Most project and process management systems fail to present large multidimensional datasets in an adequate way. This paper describes a flexible approach, which leverages OLAP technology for the processing and visualization of multidimensional project management data in the plant engineering domain. The management data includes the execution traces and the progress measures of all workflows in an engineering project. The aggregation and visualization of thisdata facilitates the analysis of a huge number of process instances which is a prerequisite for process improvement.

Workflows in Dynamic Development Processes

Process management systems are used in many domains to monitor and control processes. Development processes require specific support, which is not provided by conventional workflow systems. On the one hand, they comprise highly dynamic process parts, which cannot be defined until project runtime. On the other hand, development processes may contain subprocesses, which can be executed in the form of predefined workflows. In this paper we describe the integration of a specialized system for the management of dynamic development processes with a conventional workflow management system. This integrated solution targets the specific needs for the management of engineering design processes in the plant construction domain. It has been implemented as an extension to a commercial CAE-tool, and it will be evaluated in industrial practice in the near future.

Process Model Editing Support Using Eclipse Modeling Project Tools

Process models of manifold kinds are extensively used in the field of Business Process Management (BPM). Providing appropriate visualization and editing support for process models is of major importance. This particularly includes support for the adherence to certain modeling constraints. In this paper we report how we leverage tools and frameworks of the Eclipse Modeling Project in order to rapidly develop an editor for different kinds of interrelated process models.

On Correctness, Compliance, and Consistency of Process Models

Process management incorporates a plethora of models, which are expressed in different languages for different layers of abstraction. A holistic process modeling environment must provide means for dealing with three types of modeling constraints. First, it must ensure a model’s correctness. Second, a modeling environment must account for compliance of models with respect to models on higher layers of abstraction. Third, consistency of different models of the same language layer should be supported. In this paper, we exemplify these three constraint types and discuss how they can be enforced in a holistic modeling environment.

Dynamic Process Management Based upon Existing Systems

In the past funding periods of the CRC 476 the process management system AHEAD has been developed as a research prototype (cf. 3.4). The project T6 aims at transferring the corresponding research results into two different industrial environments. Together with innotec GmbH, we realize a process management system on top of the chemical engineering tool Comos PT. This system will allow for the holistic management of the overall administration configuration (activities, products and resources). Furthermore, we extend our application experience by also considering dynamic business processes. In cooperation with AMB-Informatik, we build a workflow management system that allows dynamic changes of workflows at runtime. This new workflow management system is also built on top of an existing one, which strictly separates build-time from runtime.

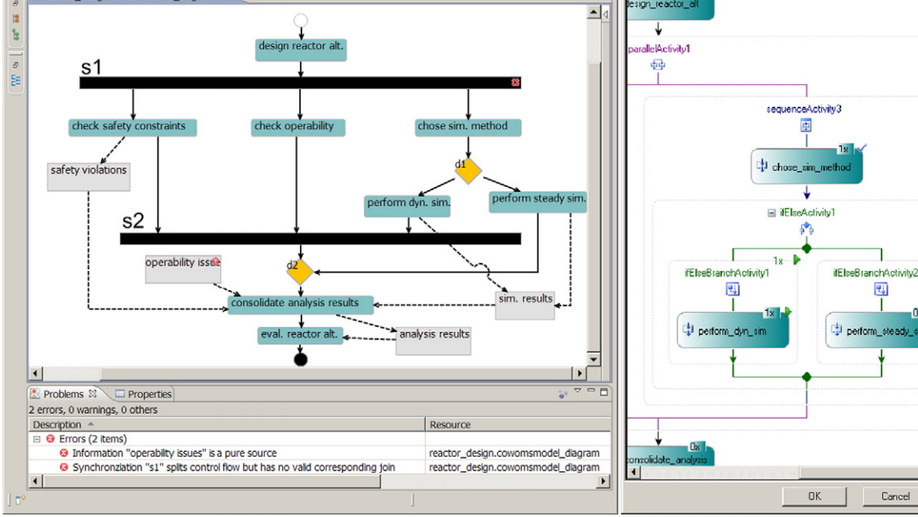

Checking Correctness and Compliance of Integrated Process Models

Models of different kinds are used in the area of business process management. Abstract process knowledge as well as executable process definitions can be visualized and edited in a graphical manner. The same holds true for models of process instances in some process-aware information systems (PAIS), which allow for dynamic modifications in a process instance during process runtime. An appropriate modeling tool must not only provide means to graphically edit different kinds of models on different abstraction layers but also detect or prevent violations of certain model constraints. These constraints comprise a model’s internal correctness as well as a model’s compliance with general process knowledge expressed in another more abstract model. In this paper we contribute an approach that allows for uniformly specifying correctness as well as compliance checks for diverse graphical process models. This is achieved by means of an integrated meta-model for models of different kinds. The integrated meta-model is referenced by a fixed set of Object Constraint Language (OCL) expressions, which specify correctness and compliance checks. We exemplify some OCL expressions and their application within a prototypical modeling tool.

An Adaptive and Reactive Management System for Project Coordination

Design processes in chemical engineering are hard to support. In particular, this applies to conceptual design and basic engineering, in which the fundamental decisions concerning the plant design are performed. The design process is highly creative, many design alternatives are explored, and both unexpected and planned feedback occurs frequently. As a consequence, it is inherently difficult to manage design processes, i.e. to coordinate the effort of experts working on tasks such as creation of flowsheets, steady-state and dynamic simulations, etc. On the other hand, proper management is crucial because of the large economic impact of the performed design decisions. We present a management system which takes the difficulties mentioned above into account by supporting the coordination of dynamic design processes. The management system equally covers products, activities, and resources, and their mutual relationships. In addition to local processes, interorganizational design processes are addressed by delegation of subprocesses to subcontractors. The management system may be adapted to an application domain by a process model which defines types of tasks, documents, etc. Furthermore, process evolution is supported with respect to both process model definitions and process model instances; changes may be propagated from definitions to instances and vice versa (round-trip process evolution).

Administration Models and Management Tools

One of the vertical columns in the overall process/product model deals with the cooperation of subprojects I1 and B4. Both study the support for reactive process management in dynamic development processes. In this section we highlight the transition from application models developed in subproject I1 to tool models for reactive management of subproject B4. We summarize our findings w.r.t. the development of management tool models as well as their connections to application models. The section focuses on a process-oriented viewpoint. Products and resources of development processes can be discussed analogously. We identify the missing parts which need to be further investigated in order to get a comprehensive and integrated process/product model, here for reactive management.

Adding Support for Dynamics Patterns to Static Business Process Management Systems

Many companies use business process management systems (BPMS) for modeling and execution support of their business processes. Many processes are highly dynamic and require changes even during execution. Common commercial BPMS fail to support such processes appropriately since they work in a rather static manner, i.e. they demand that the structure of a process is fixed before execution. Our research group cooperates with an industry partner who uses a static BPMS. This paper describes an approach that posteriorly extends this static BPMS inasmuch as dynamic changes of processes during execution are supported. The benefit of this approach is that our partner in industry gains support of dynamic processes but still use the existing BPMS and save investments related to it.

Workflow Support for Inter-organizational Design Processes

Inter-organizational design processes are inefficiently supported by management tools w.r.t. to their dynamic nature and inherent complexity. In this paper, we present an innovative framework for the definition, analysis, improvement, and management of such design processes. Key features are to bridge the gap between modeling and execution of inter-organizational design processes and the seamless execution support for both dynamic and static parts of the overall process both by appropriate process management systems. A case study is given for the conceptual design process of a plant for polyamide 6 production by hydrolytic polymerization.

Evaluating Workflow Definition Language Revisions with Graph-Based Tools

In industry, there are many workflow management systems (wfms) which have been incrementally developed over a long time. The workflow definition languages that come along with these wfms are mostly graph oriented. These incrementally developed definition languages sometimes lack important modeling constructs as well as a clear conceptual foundation. Any workflow definition language revision has to be evaluated against end user’s acceptance before implementation in the respective wfms. In this paper, we report about an industrial application of graph-based techniques in the workflow domain. We present an evaluation environment which has been developed in a graph-based rapid prototyping approach. The evaluation environment comprises editing support for workflow definitions conforming to the language’s revision. Furthermore, it provides a translator that maps definitions from the revised to the original language. Thus, the wfms can be used to enact definitions of the revised language without modifying its implementation.

A Management System Supporting Interorganizational Cooperative Development Processes in Chemical Engineering

Development processes in chemical engineering are hard to support. In particular, interorganizational development processes are concerned with the coordination of activities carried out by engineering teams distributed across several cooperating organizations. The management system AHEAD is based on long-term experience gathered in multiple application domains (soft- ware, mechanical, or chemical engineering). AHEAD sup- ports the management of dynamic interorganizational de- velopment processes by dynamic process views which al- low to manage the partial visibility of processes for ex- ternal organizations. AHEAD provides support for evolv- ing process views which are able to reflect the changes in evolving development processes. Process views serve as the basis for inter-process connection. Processes can be split top-down into subprocesses for different organizations or composed bottom-up of pre-existing processes from differ- ent organizations. Mixing top-down and bottom-up process planning and execution is possible. AHEAD allows process managers to monitor and control their intraorganizational development processes with all in- terorganizational connections to processes in cooperating organizations in a uniform modeling language

Management Support of Interorganizational Cooperative Software Development Processes based on Dynamic Process Views

Distributed software development processes are hard to manage due to their creative and dynamic character. In particular, interorganizational development processes deal with the coordination of development activities which are carried out by the engineering teams within several organizations. In this paper, we present our management support of interorganizational development processes based on dynamic process views. Process views allow to manage the partial visibility of processes for external organizations. Our approach explicitly addresses the evolution of such process views onto continuously evolving instances of development processes. The proposed concept is implemented within the process management system AHEAD, which addresses the management of dynamic and distributed software development processes.